ПРОДУКТЫ:

|

Поточная система контроля труб, полученных электросваркой методом сопротивления

The ERW In-Line uses phased array technology to inspect weld seam and the heat-affected zone (HAZ) of electrical resistance welded (ERW) tubes. The head rotation capability allows each probe independent movement from –120 to +120 degrees for weld tracking.

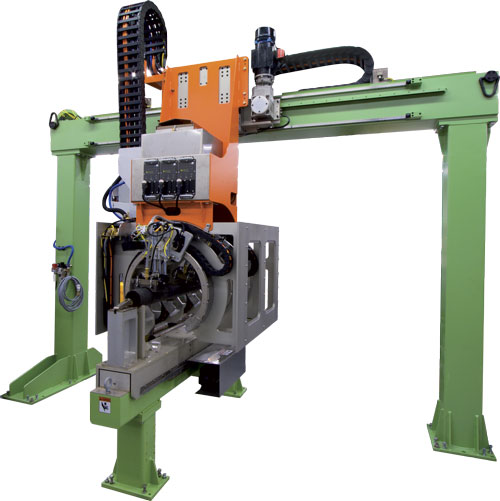

Описание:In-line Testing MachineThe Olympus mechanical solution for ERW pipe inspection is based on an small automated bridge (gantry type) that positions the inspection head in-line or off-line when performing inspections, automatic calibrations, or maintenance operations.

Calibration BenchThe Calibration Bench is an optional stand designed to perform automatic calibration and calibration check sequences at standard inspection speeds. Phased Array Weld Inspection ConceptWith Phased Array technology, a linear electronic scan is performed by moving the acoustic beam along the axis of the array without any mechanical movement. The beam movement is performed by time-multiplexing the active elements. Flaw Detection

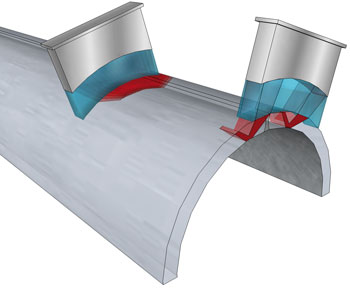

A cylindrical phased array probe is located on each side of the weld to inspect in both clockwise and counterclockwise directions. The UT beams are electronically steered to generate the desired refraction angle in the tube radial direction. Weld Profiling and Tracking

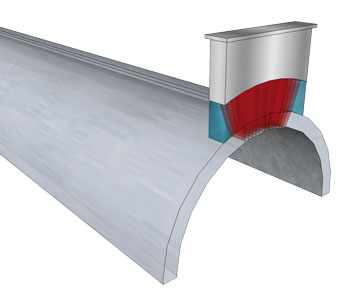

A cylindrical phased array probe located on the weld fires at zero degrees. The scarfing is automatically monitored and the weld is profiled to create a true side view of the weld for fast profile analysis. Water Wedge Concept

Each inspection head is designed with a unique Water Wedge mechanical concept providing many degrees of freedom in order to follow pipe movement and maintain perfect coupling. This versatile concept enables different types of probe holders and cylindrical PA probes to be used when inspecting different pipe sizes. Wear plates that can be attached to the inspection head are also available in different sizes to fit each pipe diameter. Pneumatic suspension enables the inspection head to follow the pipe movement and raise the Water Wedge if there is a scarfing window or butt weld between coils. The head rotation capability allows each probe independent movement from -120 to +120 degrees. Automatic Calibration

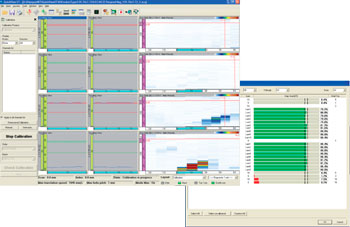

The calibration sequence is performed by moving each probe over a reference defect on the calibration tube (no tube rotation) to automatically compensate the gain of each beam for each detection gate. The calibration check sequence displays each calibration tube defect in an easy-to-interpret strip chart and weld-mapping view. Phased Array compared to Conventional UTConventional UT Inspection

When two conventional UT probes are used on each side of the weld (one for ID and the other for OD inspection), only a very narrow zone in the center of the HAZ is covered at 0 dB attenuation. As such, the UT probe's beamwidth profile shows maximum amplitude only in the center of the probe and rapidly decreases on each side. Slight mechanical movement (positioning) can result in high variations of detection amplitude. Phased Array Inspection

Using only one PA probe on each side of the weld provides wide sector coverage of the HAZ with constant amplitude. This unique solution provides constant amplitude detection within the entire inspection area, even when there is significant mechanical movement (positioning). Automatic Weld Tracking

Unique patented algorithm based on time-of-flight analysis perform automatic detection of the scarfing area and send feedback to the PLC to automatically adjust the inspection for each water wedge.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

Поточная система контроля труб, полученных электросваркой методом сопротивления

The ERW In-Line uses phased array technology to inspect weld seam and the heat-affected zone (HAZ) of electrical resistance welded (ERW) tubes. The head rotation capability allows each probe independent movement from –120 to +120 degrees for weld tracking.

Описание:In-line Testing MachineThe Olympus mechanical solution for ERW pipe inspection is based on an small automated bridge (gantry type) that positions the inspection head in-line or off-line when performing inspections, automatic calibrations, or maintenance operations.

Calibration BenchThe Calibration Bench is an optional stand designed to perform automatic calibration and calibration check sequences at standard inspection speeds. Phased Array Weld Inspection ConceptWith Phased Array technology, a linear electronic scan is performed by moving the acoustic beam along the axis of the array without any mechanical movement. The beam movement is performed by time-multiplexing the active elements. Flaw Detection

A cylindrical phased array probe is located on each side of the weld to inspect in both clockwise and counterclockwise directions. The UT beams are electronically steered to generate the desired refraction angle in the tube radial direction. Weld Profiling and Tracking

A cylindrical phased array probe located on the weld fires at zero degrees. The scarfing is automatically monitored and the weld is profiled to create a true side view of the weld for fast profile analysis. Water Wedge Concept

Each inspection head is designed with a unique Water Wedge mechanical concept providing many degrees of freedom in order to follow pipe movement and maintain perfect coupling. This versatile concept enables different types of probe holders and cylindrical PA probes to be used when inspecting different pipe sizes. Wear plates that can be attached to the inspection head are also available in different sizes to fit each pipe diameter. Pneumatic suspension enables the inspection head to follow the pipe movement and raise the Water Wedge if there is a scarfing window or butt weld between coils. The head rotation capability allows each probe independent movement from -120 to +120 degrees. Automatic Calibration

The calibration sequence is performed by moving each probe over a reference defect on the calibration tube (no tube rotation) to automatically compensate the gain of each beam for each detection gate. The calibration check sequence displays each calibration tube defect in an easy-to-interpret strip chart and weld-mapping view. Phased Array compared to Conventional UTConventional UT Inspection

When two conventional UT probes are used on each side of the weld (one for ID and the other for OD inspection), only a very narrow zone in the center of the HAZ is covered at 0 dB attenuation. As such, the UT probe's beamwidth profile shows maximum amplitude only in the center of the probe and rapidly decreases on each side. Slight mechanical movement (positioning) can result in high variations of detection amplitude. Phased Array Inspection

Using only one PA probe on each side of the weld provides wide sector coverage of the HAZ with constant amplitude. This unique solution provides constant amplitude detection within the entire inspection area, even when there is significant mechanical movement (positioning). Automatic Weld Tracking

Unique patented algorithm based on time-of-flight analysis perform automatic detection of the scarfing area and send feedback to the PLC to automatically adjust the inspection for each water wedge.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||